Background: This hot feed / effluent heat exchanger has a history of leaking that extends back 10 years and includes clamping and leak-sealing by outside contractors, as well as changing the gasket styles on at least two occasions to “upgraded” styles suggested by manufacturers. The most recent change in 2010 was to a kamprofile gasket with Mica/Graphite/Mica sealing elements. At that time, the flange surfaces were inspected, the new gaskets were installed, and the flange was tightened per refinery procedures. However the Tubesheet-to-Shell joint developed a small leak shortly after start up, and a steam ring was installed.

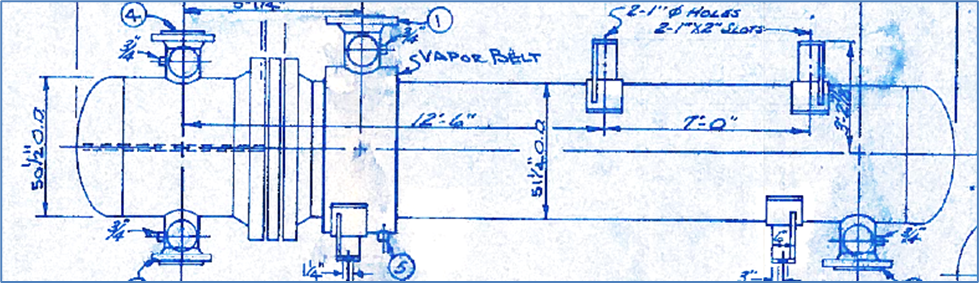

This is a TEMA type BEU exchanger with only one joint (channel – tubesheet – shell), with two gaskets and one common set of studs. The stud material was originally B7, but has been upgraded to B16. The joint utilizes 64, 1-1/8” studs that were torqued to a final value of 700ft.lb.

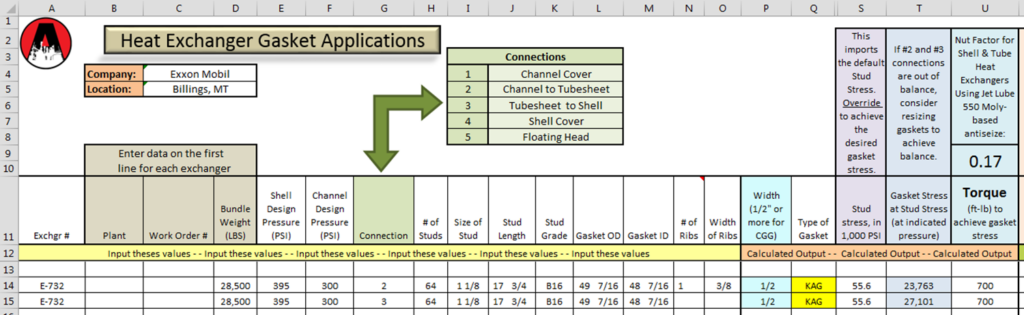

Analysis: The information provided by the client was loaded into the Exchanger Gasket Workbook to analyze the gasket seating stress under operational conditions. Barring defective components – whether flanges or gaskets – heat exchangers leak due to low gasket seating stress. For this reason we always look first at the gasket seating stress at full operating pressure. Regardless of the “Y” value of the gasket, we have found that reliable sealing of graphite-faced gaskets requires a gasket stress between 10,000 and 40,000-psi. If possible, we work to achieve a gasket stress in the 20,000 to 25,000-psi range. Not only is that tight enough to provide a great seal at start up, but it is also tight enough to offset the inevitable relaxation found in heat exchanger joints.

Given the leakage history on this unit, we anticipated a low gasket stress. However, the gaskets on this exchanger were loaded to nearly ideal levels. (The final page of this analysis is a snapshot of the Exchanger Gasket Workbook.) The question that must be resolved is how an exchanger that is designed to deliver 25,000-psi gasket stress can begin leaking shortly after start up. What factors might have contributed (historically) to the low-stress conditions that allowed leakage?

A full review of the equipment drawings and the related documents led us to two significant factors related to the equipment and gasket

designs, and two additional factors that were assembly related. Chief among these contributing factors was the threaded tubesheet.

The equipment drawings show (below) that the 64 holes in the tubesheet are threaded for the 1-1/8” studs.

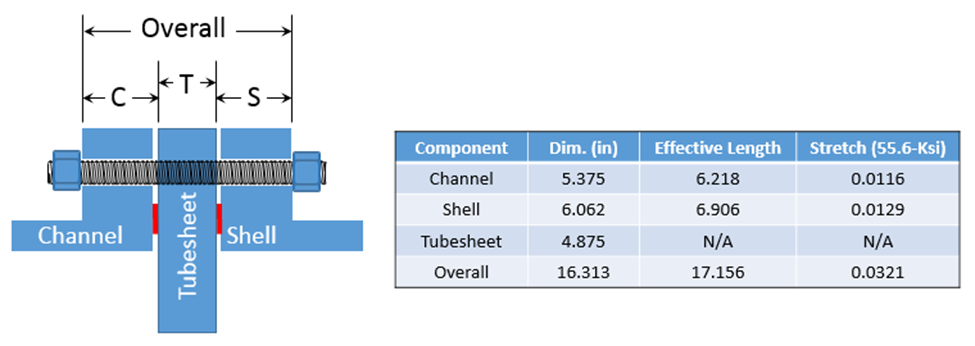

As currently configured, the portion of the stud on the channel side acts independently of the portion of the stud on the shell side. The total amount of stretch in the stud is 0.0245”. However, if the tubesheet were drilled out, the full length of the stud would stretch under tension, providing 0.0321” of stretch – a 31% increase! For a flange that leaks habitually, this is a huge improvement of stud response.

It is interesting to note that the gasket stress drops more than the stud stress, because of the effect of the hydrostatic end-load on the joint. The table below summarizes the resultant gasket stress if there were a relaxation of 0.006” on each side of the tubesheet. (This is not an excessive estimate.) Each side is considered independently, because they are isolated from each other by the threaded tube sheet. Notice that the stud stretch and

stud stress are directly related, because the stud is a linear spring. But the gasket stress drops far more, because of the stud stress that is diverted to offset the hydrostatic end force in the joint.

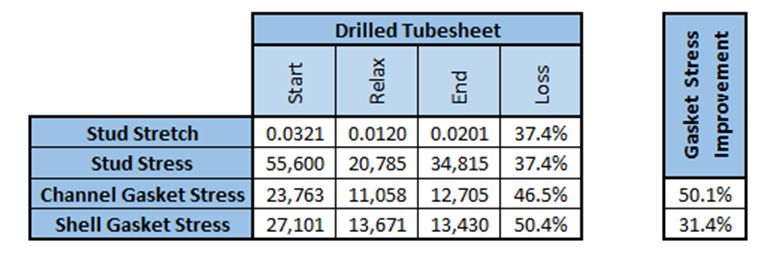

The table below models the same scenario – a relaxation of 0.006” on each side of the tubesheet, for a total of 0.012” relaxation. However, in this case the tubesheet has been drilled out, allowing the full stretch of the stud to interact with both gaskets. Compared to the above chart, the percentage of stud stretch and stud stress drops far less, and the resultant gasket stresses are improved 30 – 50%!

Clearly, the short studs amplify the loss of gasket stress when relaxation occurs. Because of these dynamics, ERIKS recommends drilling out all threaded tubesheets. The purpose of the stud is to stretch to maintain gasket stress, and threaded tubesheets limit the ability of the stud to do so. We have clients who are now routinely drilling out tubesheets whenever they come across them.

If a refiner feels that they need to retain the ability to hold the Tubesheet-to-Shell joint tight while removing the Channel, they can do this with only one stud in four. So even if it is felt that drilling all the holes is not prudent, drilling three out of four holes would still improve the stud load on the gasket, while preserving the ability to remove the Channel independently.

Summary: While a simple numerical analysis seemed to indicate that there was adequate seating stress on the gaskets to prevent leakage, the fact that leakage was regularly occurring indicated underlying problems that were resulting in low gasket stress.

Beside issues related to the specific style of gasket utilized, the re-use of studs, and the lack of a post start-up retorque, the greatest contributor to the loss of gasket stress was the threaded tubesheet; which, in this case predated any changes in the gasket style. This conclusion is in line with field observations of leaks that are related to threaded tubesheets.

Recommendation: Drill out all 64 holes in the threaded tubesheet to allow the stud the maximum stretch with the calculated stud stress. As a bonus, this will make assembly easier, as the stud does not have to be tightened from both ends.