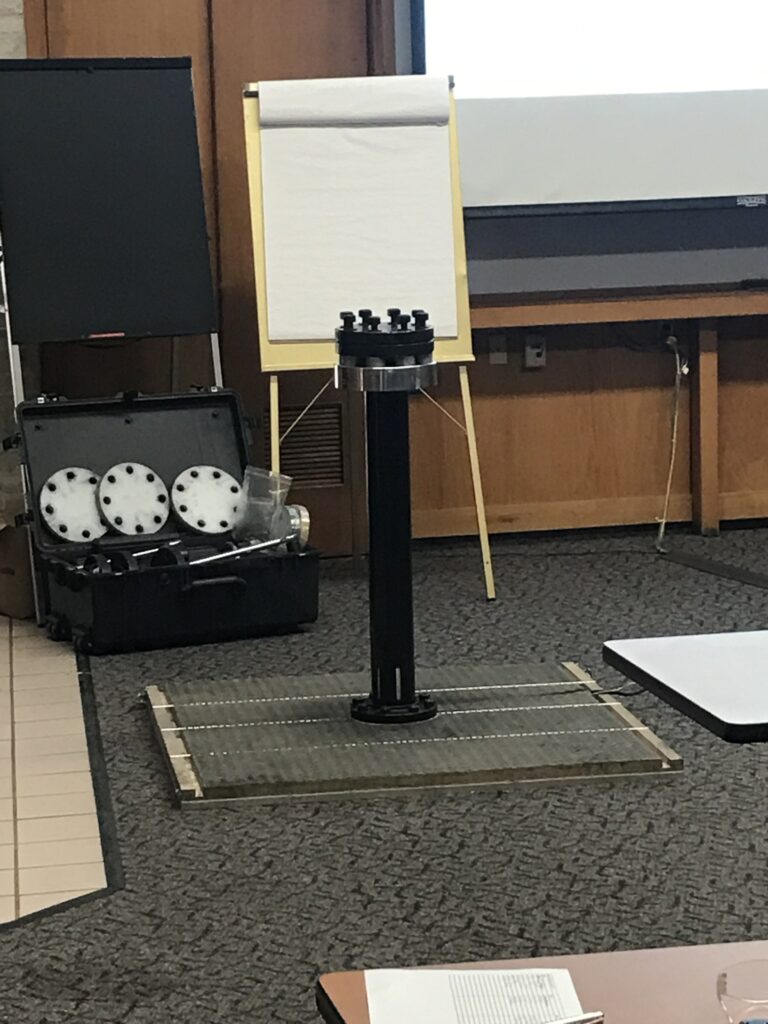

Boost plant safety and efficiency with LGG Industrial’s FADU training tool. This interactive program teaches maintenance, operations, and engineering teams the value of controlled bolting for optimal flange joint integrity and reduced downtime. This customized on-site gasket and bolting training, covers proper bolting techniques and pre-turnaround prep.

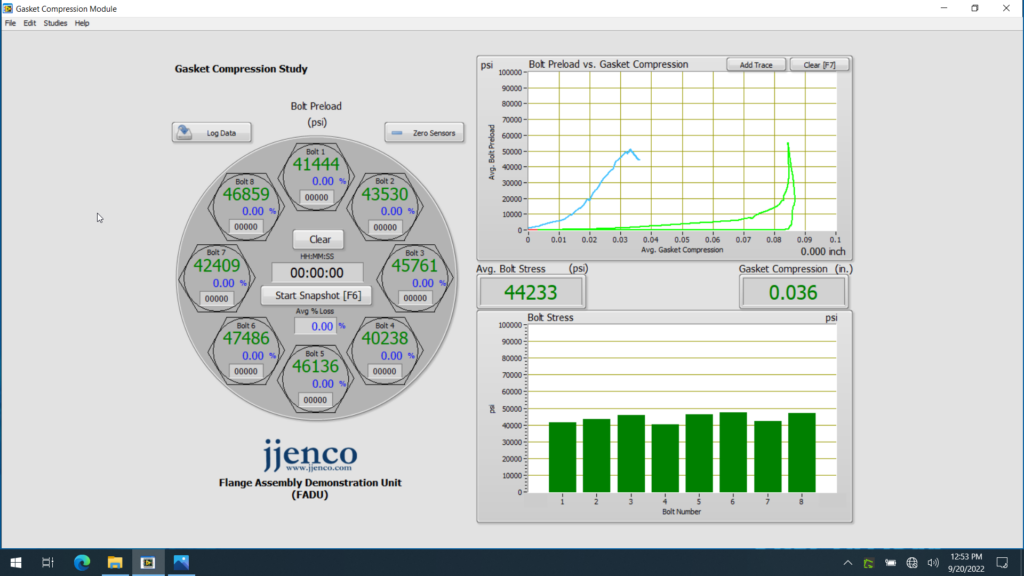

Attendees can observe the variability in stud load created by not using a controlled bolting program. Using a single stud with a load cell on the FADU unit, each attendee is given the opportunity to use their best judgement to achieve a common torque target. Once each participant has tightened the nut, the results are graphed to demonstrate the inherent scatter that results from hand-tightening procedures.

This module shows the importance of a star cross pattern, highlights crosstalk between the studs, and demonstrates how stud stress relates to torque. This module enables attendees to bolt up the flange using their plant-specific torque and bolt-up procedure. It clearly shows the variability of bolt load based on the amount of lubricant applied to a stud(s).

This exercise shows the same information as gasket compression but with a RTJ (Ring Type Joint) gasket rather than a Standard Pipe Flange Gasket. The same types of variability noted above apply.

This module demonstrates the big difference that little differences can make. Torque preload illustrates the importance of proper lubrication, nut up vs. nut down, and washer vs. no washer. It can also compare different lubricants, washer types, and torque wrenches.

Take a leap toward industrial excellence and unleash the power of tailored solutions and trusted service. We’re here to help you optimize operating performance and reduce downtime — no matter your industry or the unique challenges you face. Click to find an LGG Industrial location near you.